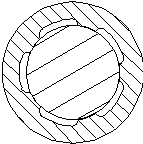

When faced with a small I.D. bottle, traditionally designed core rods result in reduced productivity. Often the core is starved for air and the heads easily bend or snap off when stripping performs and non-blown containers. That is why we have created Clover FlowTM to solve these and other problems which plague small cores in Injection Blow Molding.

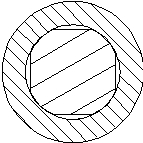

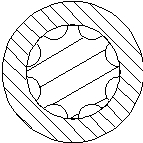

| Traditional Core | Scalloped Core | Clover Flow TM | |

|

|

|

|

| Air Flow | Poor | Good | Excellent |

| Head Rigidity | Poor | Poor | Excellent |

| Bearing Surface | Poor | Poor | Excellent |

As a standard, Hammonton Mold, always uses Clover Flow TM for all small I.D. tools such as mascara vials, test tubes, and liqueur miniatures. There is no additional cost to you for this improved technology. Over the life of the tool you will see a marked decrease in core rod repair expense resulting from snapped heads. Our goal, as always, is to help you become more profitable.